Relevelling of the FEB warehouse concrete floors and soil stabilization

THE PROBLEM

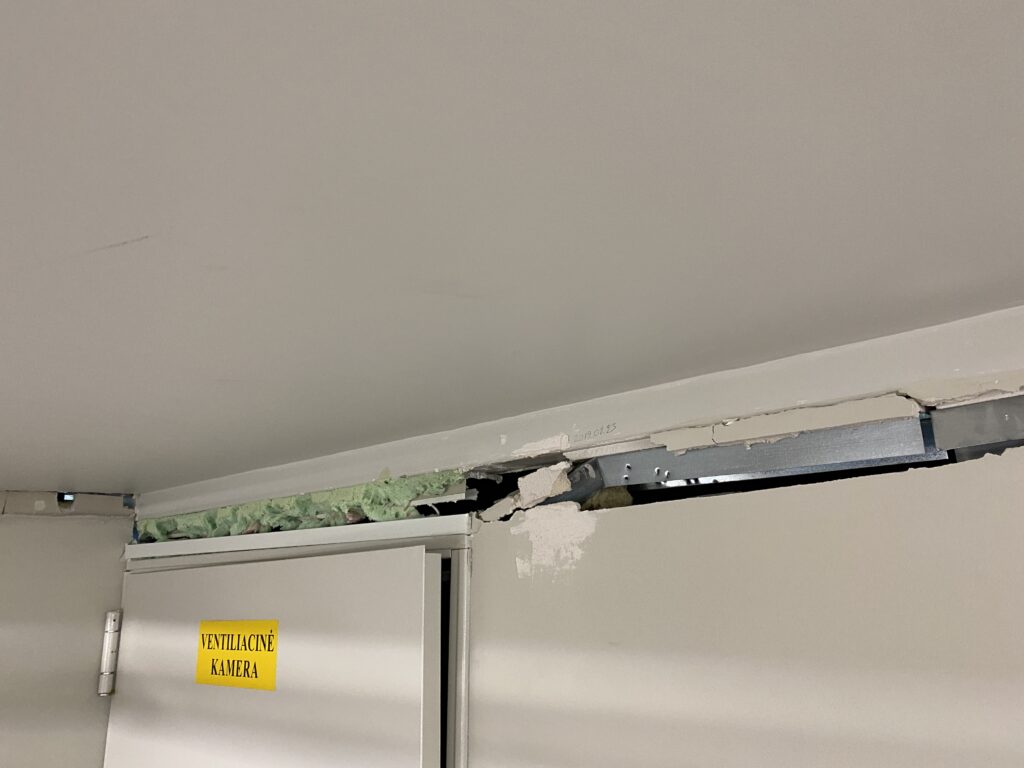

FEB logistics centre is the heart of the company, which operates 24h a day. Even a brief stoppage of work of the centre would be very challenging and costly for the company. However, floors of the warehouse had to be lifted and soil under the floor compacted, because concrete slabs had started to move under the weight of forklifts.

WORK PROCESS WITH URETEK TECHNOLOGY

URETEK Baltic performed inspections to ascertain that loads created extremely strong pressures in the vicinity of expansion joints. At first, it was urgent to restore the substrate of concrete slabs to avoid their breakage. It was impossible to use any solution that required stopping work, as it would have been too costly. It took six hours to stabilise 150 square metres of floor area without encountering any problems or disturbing the ordinary operation of the warehouse. URETEK floor lifting technology SLAB LIFT allows filling the voids under the floor with patented expanding geopolymer, which is specifically designed for this type of work.

THE RESULT

Expanding geopolymer strengthened subsoil and restored contact between floor and underfloor. Work performance was measured by laser level, which registers lift at an accuracy of 0.5 mm. To minimise any disturbance to the client, the URETEK Baltic team carried out works by sections. The total time spent on work was six hours and the first fully loaded forklift was allowed in the area already 10 minutes after completion of works. Meanwhile, the client did not have to remove goods from shelves, on the contrary – all shelves had to be as loaded as possible to ensure maximum compaction of soil under the floor.