The foundation is one of the most important, if not the most, part of a building. The entire building relies on the foundation, and its durability determines the durability of the entire thing. The foundation of the building has to be built so that it withstands the weight and load of other elements. A building’s and its foundation’s construction starts with preliminary work, which can not be ignored.

Preparing the soil by its compaction and leveling, is an important part of the construction process. This gives it the required flat base that offers an important support not only for the building, but for roads and other different building constructions as well. The compression process gives the soil, that is under the foundation, a bigger endurance and stability. It is important to know why this process requires careful attention and what could happen, if this step is skipped or carelessly executed. And most importantly- how to deal with consequences that have occurred from poorly compacted and leveled soils.

What is soil compaction?

The majority of constructions are supported by soil that is underneath them. To enable construction of a building or other facility, air and water particles must be removed from the soil and then it has to be leveled. That way the treated soil can sufficiently and firmly support the construction.

Soil compaction means increasing the density of soil, sand or some other solid soil layer by pushing out water or air from it. This is done by applying load to soil with the help of mechanical means. This way the soil’s volumetric weight and carrying capacity increases, which ensure the load receptivity coming from the building.

The compression’s main goal is to increase the shear strength and the related load capacity. Through the process however, the stiffness of the soil is also increased to prevent future deformations, for example through moisture content and frost.

The result from the compressions depend on many different factors such as:

- The nature and type of the soil – it can mean compositions from sand, clay, soil or granular;

- The thickness of the compacted soil layer;

- The moisture of the soil;

- Time, that is spent on compaction;

- Of the work that is done for compaction- the weight, type, vibration, number of repetitions etc of the used device

What is soil leveling?

Soil leveling, as the name itself says, means leveling the ground, to remove bumps, dimples or other bigger unevenness. The operation is carried out in the preparation phase of the new construction project.

One of the main purposes of soil leveling is to protect the foundation from water damages. Leveling the soil under constructions or around it, ensures water from flowing away from the building and not into the soil layer under the foundation. If the soil layer is not leveled or is poorly done, the water can flow towards the house. This can gather around the foundation and saturate the surrounding soil, causing the building to become unstable.

Afterwards, it is possible to carry out soil work around the house. For instance on properties, where the missing drainage ruins the foundation, leveling the soil can repair the situation.

Why is soil compaction important?

If proper geological studies were not done before building a house and the house is built on a weak land, or the land has been poorly prepared before building a foundation, as in compacted and leveled, it can lead to the process when the soil as well as the house start to subside.

A subsidence is a process that is a result of the environment, as a result of substandard works or due to changes in the soil, the building’s foundation could move downwards. Land subsidence can be caused by geological, manmade or seasonal reasons:

- High spring waters can wash away a lighter layer of soil, such as sand;

- Bigger trees that grow near the foundation can, especially during hotter periods, suck out moisture from the soil so much that it could cause the soil or other soil layer to contract;

- Water that has flown out from a broken or leaking sewage, can sometimes soften or even wash away the ground surface, resulting in a movement of the ground and therefore the building;

- If a building is near a high traffic area, the strong vibrations coming from it could lead to ground movement.

- Foundation works, that have been done with poor quality, could cause subsidence problems, especially during water damages.

Although, reasons why a house’s foundation or floors subside are different, they are still frequently caused from the very first building steps. For this reason, it is very important to be cautious about the soil’s compaction and leveling.

What does house subsidence entail?

Different cracks in the inner and outer walls, gaps between the floorboards and the walls, sloping or partially sunken floors, slanted or jammed windows and doors are just a few concerns that subsidence can bring up.

Over time subsiding foundation can bring up serious problems:

- Damages to walls and floors are harder to repair or they are even irreversible;

- Cracks that have become bigger and bigger over time allow wind and moisture to enter the house, causing mold over time;

- Heat loss increases, the dwelling is colder and as a result the energy efficiency of the building decreases;

- Water and heating pipes can break;

- Malfunctions of electrical installations can occur.

Problems that are caused from the house’s or foundation’s subsiding are expensive. A lot of money is frequently spent on repairing damages, but the core of the problem is not dealt with and no work is undertaken to stabilize the foundation.

How to deal with the consequences of poorly compacted soil?

If for any reason the foundation of the house has begun to subside and as a result the whole building has started to do the same, the problem must be dealt with as soon as possible. Then neither the soil leveler nor the surface hardener will help, you have to approach subsidence in a different way.

Stopping the house from subsidising and restoring the foundation using conventional methods is a time consuming and resource-intensive job. Solving the problem with the outdated approach means emptying the rooms, breaking up and removing the concrete floors, compacting the soil and pouring new floors. This puts the owner of the house in front of a difficult question- should they start a time- and money consuming process that forces them to be away from home for a long time, or postpone the solution of the problem into the indefinite future, knowing that the situation will constantly worsen? This way it seems like the only thing left is to make a bad or worse choice.

If only there was a solution that thickened and stabilized the building quickly and cleanly and would not need additional preparations such as moving out of the house and replacing furniture. What if the cracked walls and cracks between walls and floor tiles could be fixed in a day, without waiting for the new concrete to harden? Seems too easy of a solution to be true?

How can URETEK help?

Works performed by the soil improvement enterprise URETEK are, due to their innovative technology, a highly valued alternative for raising and restoring building foundations or floors. This does not require excavation or demolition, thus contributing to both human comfort and environmental protection. Also the technology developed by URETEK does not cause vibrations or disturb nearby buildings.

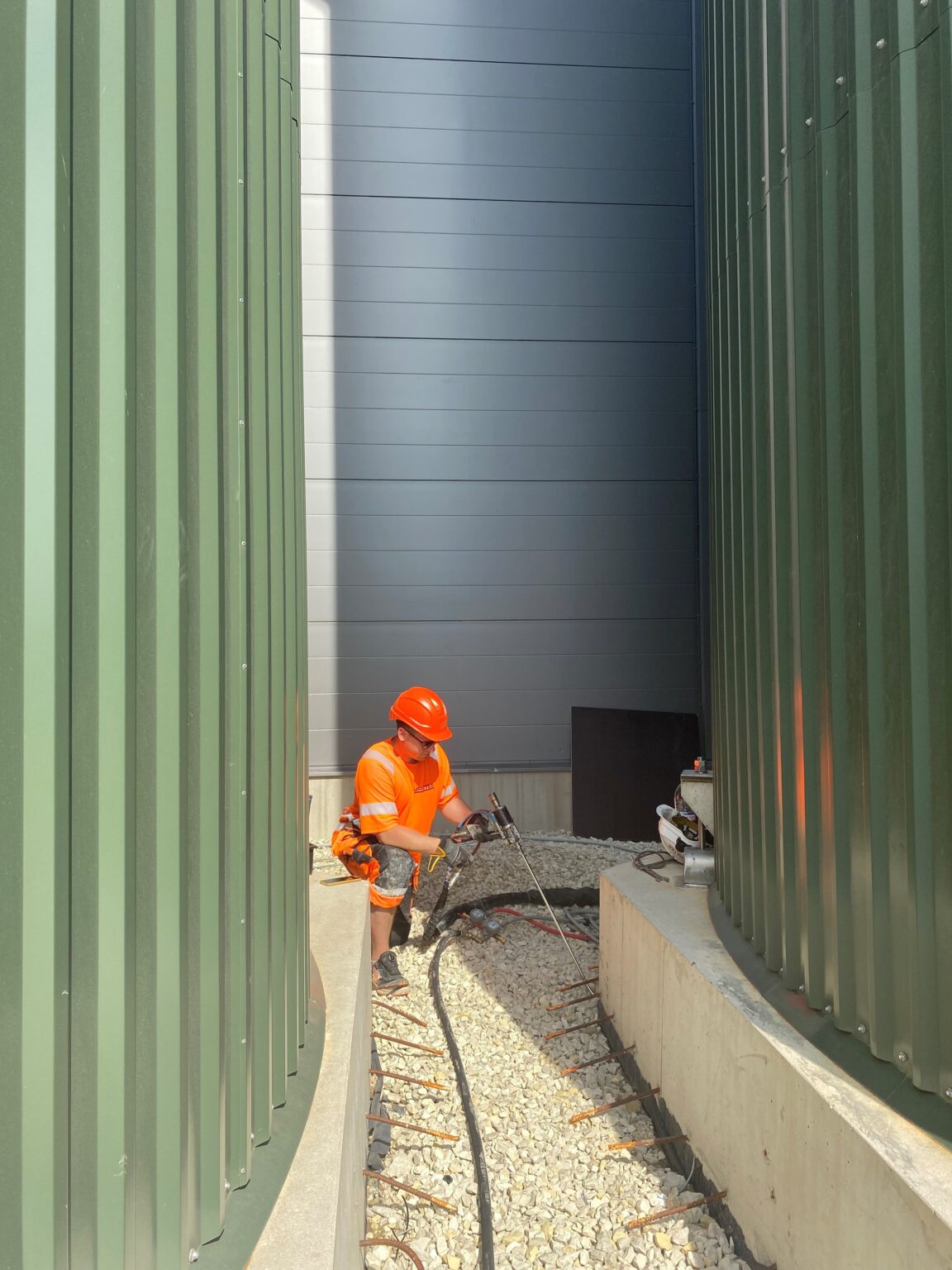

URETEK uses injection technology of geopolymers, which allows it to approach the mentioned problems in a new and convenient way. URETEK offers a technological solution, with which two component geopolymer resins inject the ground. The nature of the problems in soil, which is the cause of subsidence of the foundation and floors, is reached through a 12-32mm wide borehole and an ecologically neutral resin or geopolymer resin mixture is injected into it. The resin is inserted into the soil where it expands until it hardens, filling all the voids and cavities in the soil. Under the influence of resin injection, the house or other structure rises up and moves back to the original designed height. The soil layer is compacted and thereby ensures the stability of the building.

It is not required to move out of the house or even move furniture for this type of procedure. Daily use of the building may continue during the works. Usually it only takes one to three days to complete the work and the work site remains clean and dust-free.

Get in touch with us and we will stop your buildings from subsiding.