Lifting of concrete slabs and soil compaction at Alavere silage storage facility

THE PROBLEM

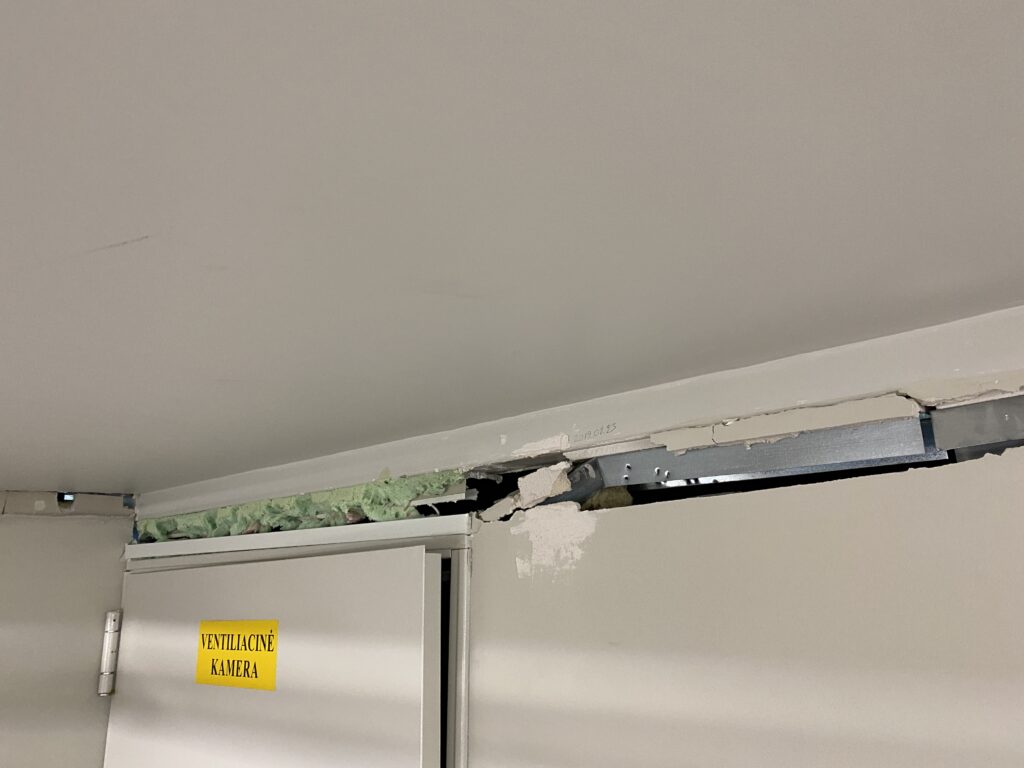

Over the years, silage effluent had caused the concrete collection channels of the silage storage facility to deteriorate and leak. The leaking effluent seeped into the soil, washing out the ground beneath the concrete slabs and contaminating the adjacent field. As a result, the underlying soil weakened and lost its load-bearing capacity.

The facility had already been repaired 2–3 times in the past without success, prompting the company to turn to the URETEK Baltic team for a lasting solution.

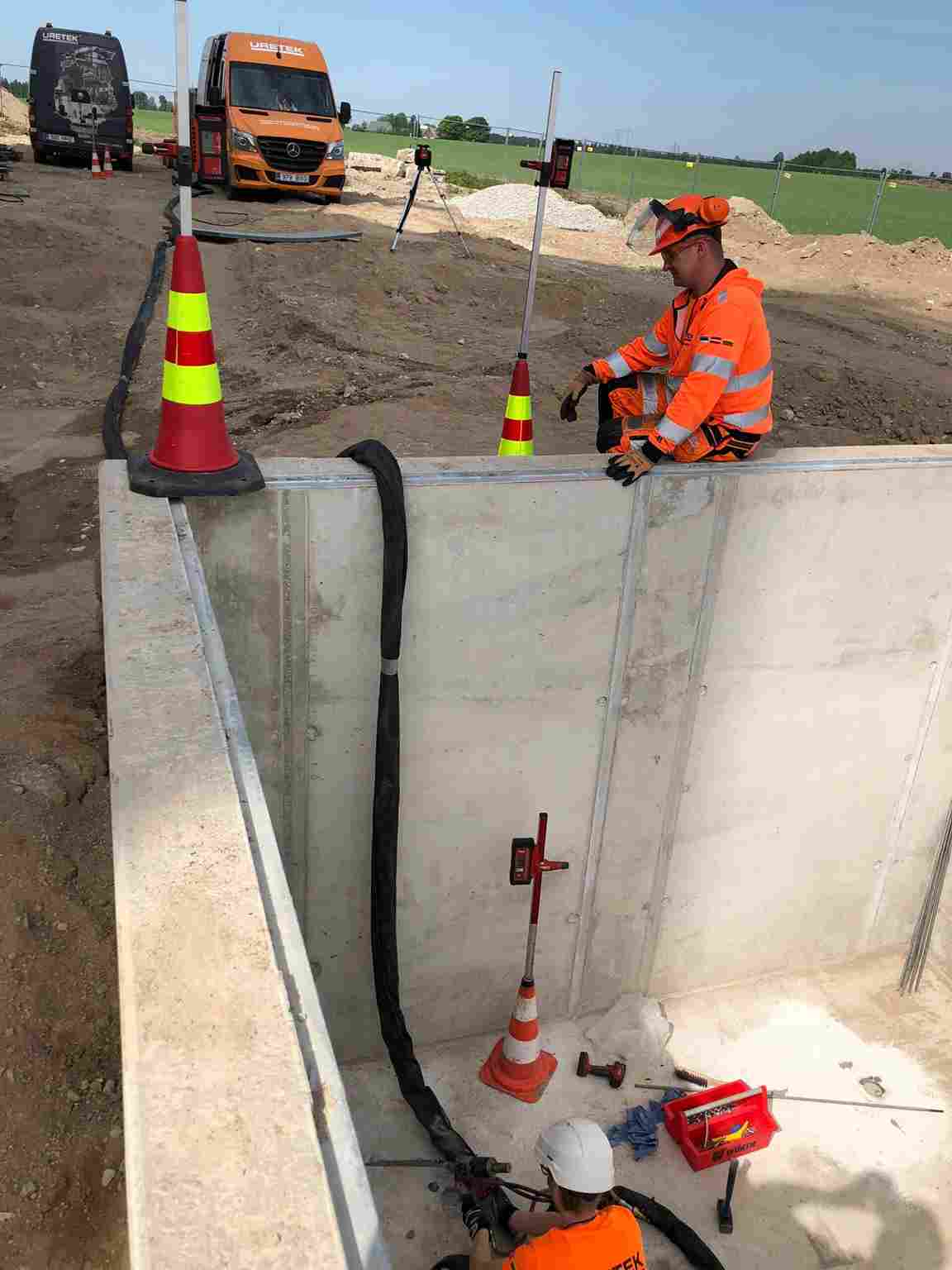

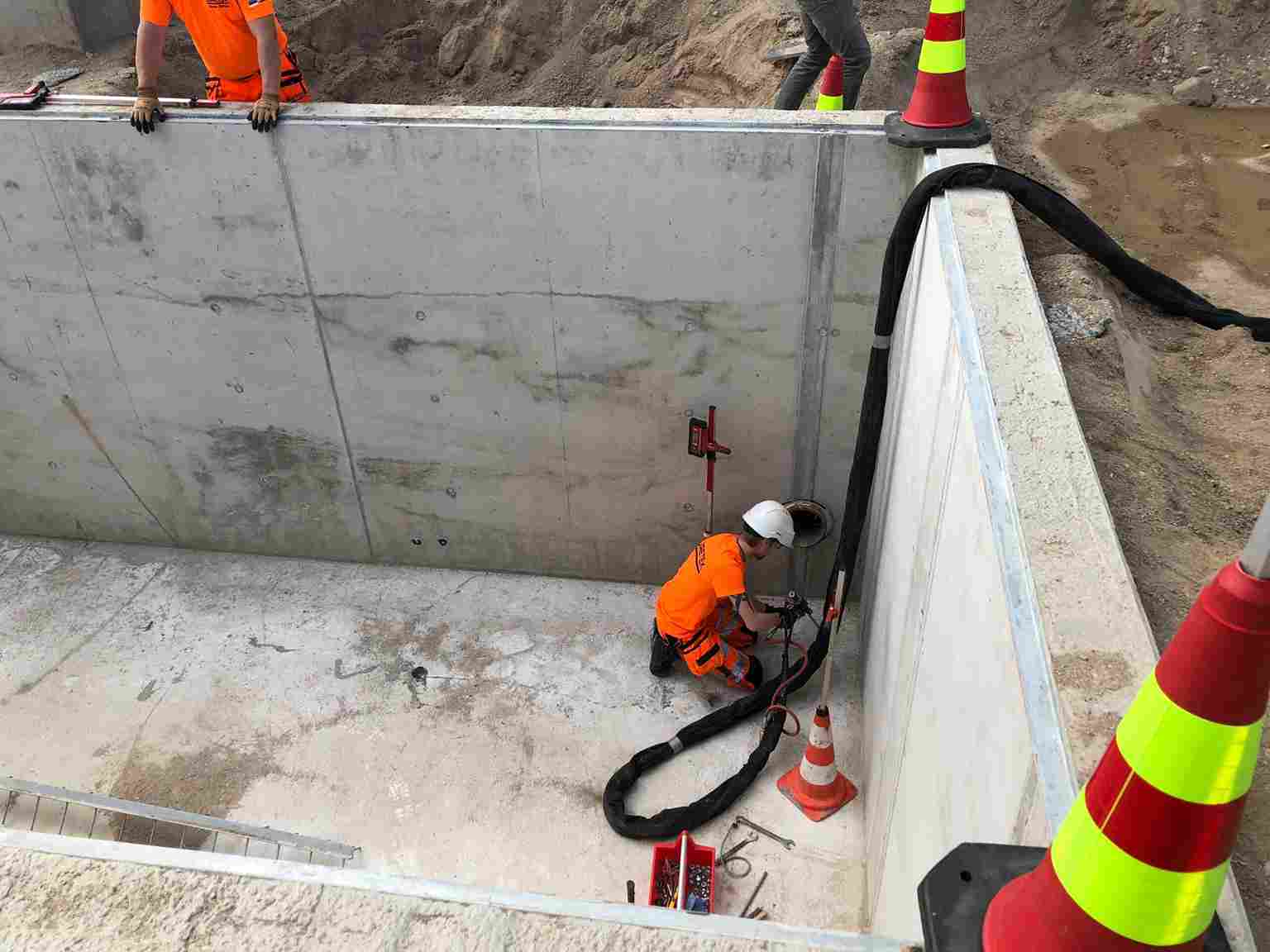

WORK PROCESS WITH URETEK TECHNOLOGY

Using URETEK technology, voids in the soil were first filled with geopolymer resins to restore the soil’s load-bearing capacity. Then, the areas behind the collection channels were injected with geopolymer resin to stop further leakage into the soil.

THE RESULT

The entire operation was completed by URETEK Baltic technical team in just 4 hours. In contrast, traditional methods would have required 2–3 weeks to demolish and rebuild the concrete slabs, and the cost to the client would have been three times higher.

URETEK Baltic successfully stabilized the soil and halted the leakage of silage effluent within 1 day.