Frequently, the equipment on construction and mining platforms lacks reliability due to their poor quality or ineligibility for particular operation. However, the problem may often be related to land subsidence.

Even the smallest deviations occurring in soil due to subsidence may cause disruptions in the operation of machines and mechanisms that require precision and cause excess burden on such equipment. Eventually, such situation may cause remarkable disturbances in operation and be costly in monetary terms. Ignoring the problem may lead to breakdown of the equipment, resulting in work stoppage and costly repairs (technical maintenance), loss of productivity and, in some cases, risk of danger.

First signs of potential problems

Division operator is recommended to check the alignment of equipment. Frequent deviations include:

- Unusual noise generated by equipment;

- Abnormal wear and tear of equipment, especially in case of conveyor belts and crane tracks;

- Excess wear and tear of tracks and surfaces under equipment due to excess vibration that causes land subsidence.

The most common causes of subsidence (gradual collapse, compaction or sinking of ground surface) include problems related to drainage, poorly compacted filling material and mechanical vibration.

It is crucial to apply early countermeasures

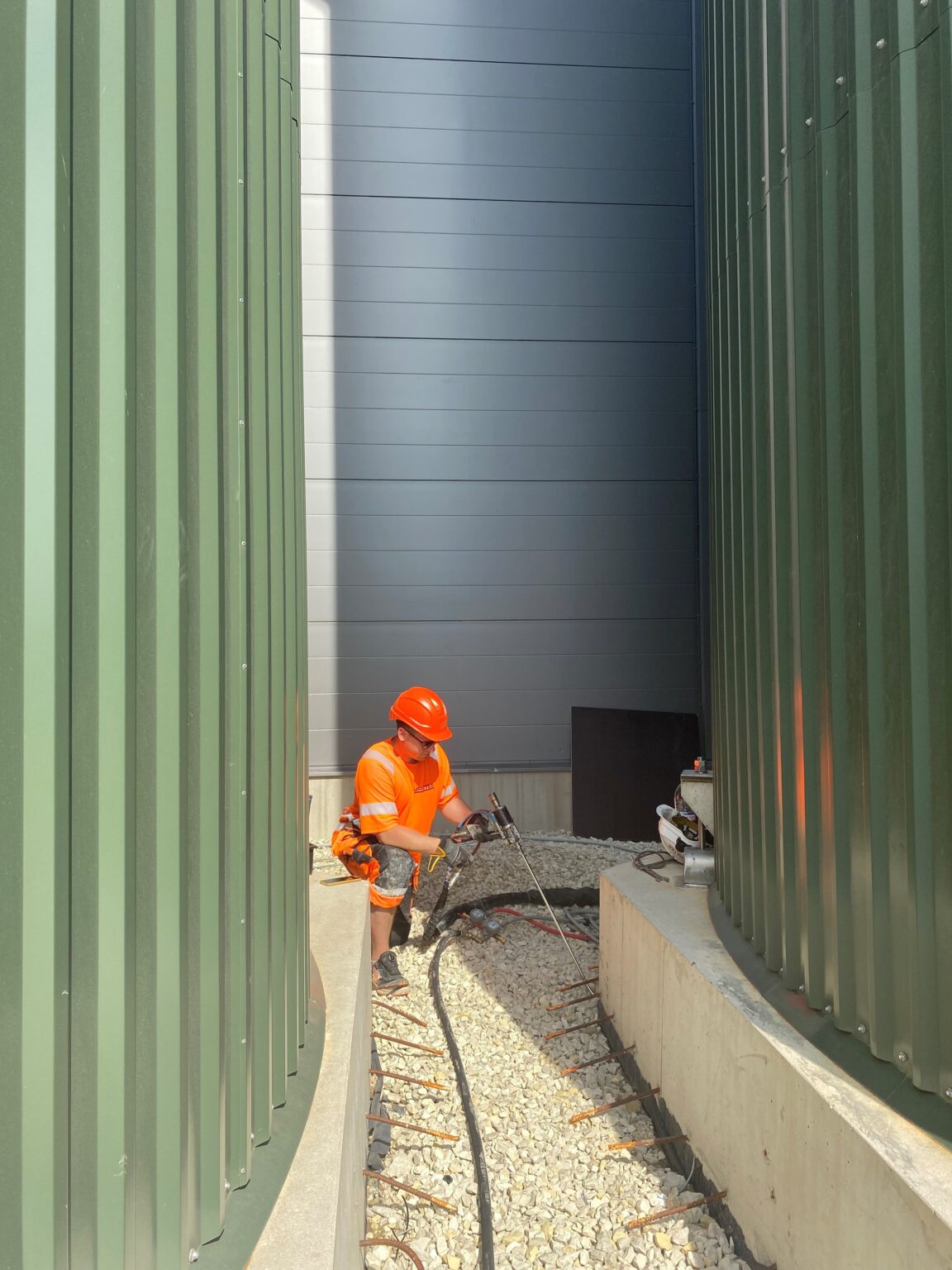

It is always advisable to stop land subsidence before equipment fails, as it allows minimising expenses related to work stoppage and repairs. By using modern soil technology methods, it is much easier and quicker than people would think. For instance, URETEK resin injection technology is a reliable, convenient, effective and cost-efficient alternative solution instead of traditional methods such as concreting or cementing. URETEK technology involves using low pressure to insert resin in unstable soil or rock that has fallen apart or suffered structural damage due to compaction, in order strengthen it. Operative and effective URETEK technology can also be applied in a situation, where it is impossible to intervene in the operations on construction site. Depending on volume, the procedure may take a few days and it can be performed parallel to construction works and without taking breaks. That’s what makes the method so flexible.

Light and yet durable resins used in URETEK technology are sustainable, have low environmental burden and help performing variety of technological and geotechnical tasks. Areas of application include e.g. decommissioning of fuel tanks, underground storages, water pressure pipes, stormwater pipes and tunnels, also filling large cavities, voids and even abandoned mines with bulk material.