Foundation subsidence

Soil compaction and foundation stabilization of the Riga Cathedral, a UNESCO World Heritage Site

Keywords

Stopping the subsidence of a historic building in Vilnius Old Town

Keywords

Stabilisation and re-levelling of the concrete floor of the Rimi shopping center

Keywords

Subsidence of the floor! How to lift the foundation?

CONTENTS

→ Introduction

→ Help – my house’s foundation is subsiding!

→ How to repair the subsidence of the foundation or the floor?

→ How do URETEK geopolymers help to raise and stabilize the foundation?

→ URETEK Baltic compacts the soil

→ Introduction

→ Help – my house’s foundation is subsiding!

→ How to repair the subsidence of the foundation or the floor?

→ How do URETEK geopolymers help to raise and stabilize the foundation?

→ URETEK Baltic compacts the soil

Introduction

Renovating an old house can be even seen as an exciting hobby with the same goal for the whole family – to restore a house that will be turned into their new home. This process often takes years, if not decades. When renovating, the list of things that need to be repaired is often long enough to leave the smaller things in the background. The priority of work seems to be divided. This is how a small crack in the wall may go unnoticed at a first glance. However, that small crack, which initially looks like a beauty flaw, can be a sign of something bigger – the foundation or floors of the house are subsiding. In that case, concrete lifting is needed. That may require different concrete leveling equipment depending on the project, such as concrete hoisting equipment, concrete lifting hooks, concrete pipe lifting equipment, precast lifters, precast lifting clutch or concrete panel lifting clutches. It is clear that this work needs professional help.

For the most part, owners of old houses have taken into consideration that unexpected and unpleasant setbacks may arise that will require immediate action and extra cost. Owners of new houses expect that the time and material costs will be much lower. However, the subsidence of the foundation and floors, unfortunately, more often than we assume – is also a concern for new houses. A decrease in the efficiency of underfloor heating in a new building may indicate the subsidence of the floors, but there may be other similar problems that also arise with old houses.

Help – my house’s foundation is subsiding!

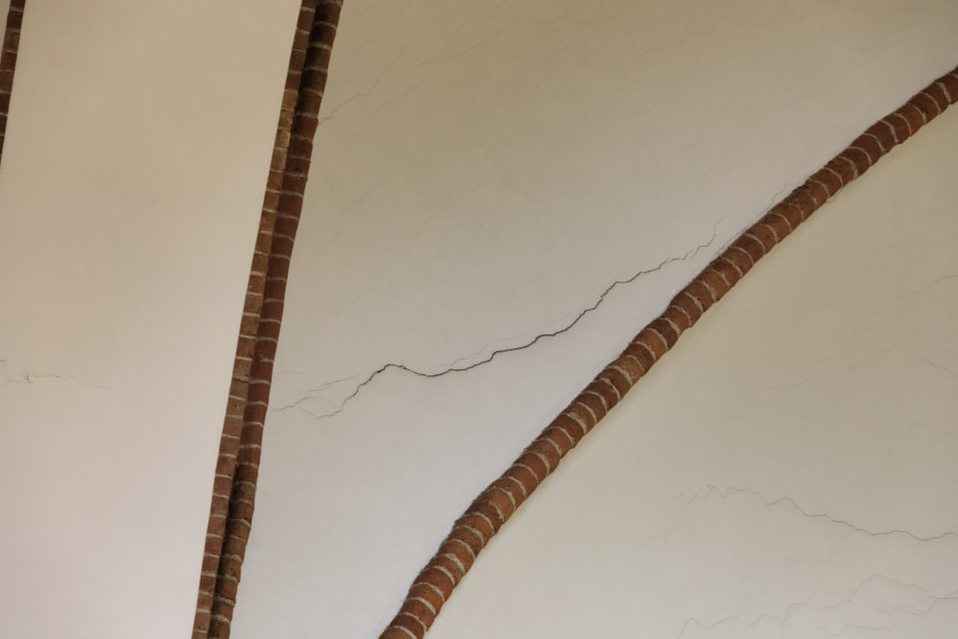

Any cracks in the interior and exterior walls, gaps between the floorboards and the wall, sloping or partially subsided floors, jammed windows and doors are situations that can indicate a serious danger to the entire house – the foundation of the house is subsiding! The subsidence of a building is a process where the foundation of the building begins to move downwards due to the influence of the environment, as a result of poor quality work or changes in the properties of the soil. In this case, foundation or concrete lifting is necessary! There are many options for that. Lifting precast concrete, concrete floor lifting, cement slab lifting or precast lifting are just some of them.

At first, it might seem like raising and stabilizing the foundation is not needed because major damage and longer-term problems are not immediately apparent. However, urgent action is needed on this issue. The subsidence of the foundation will lead to more serious concerns over time:

- damage to walls and floors will be more difficult or even irreversible to repair;

- cracks that become larger over time allow wind and moisture to enter the house, creating mold over time;

- heat loss increases, the house is colder and becomes less efficient;

- water and heating pipes can break;

- problems in electrical installations occur.

A lot of money is often spent on repairing the damage, but the core of the problem is not addressed and no foundation stabilization work is done. In this way, various worries start to reoccur, requiring more costs on house maintenance. The most effective way to protect a building from major damage is to stabilize it and restore the foundation to its former state. You can do that by hiring a professional to help you out. Special equipment is needed for cement lifting, foundation lifting, or concrete driveway lifting.

There are many reasons why the foundation and floors of a house have started to subside, and they often arise during the construction of the house. Here are some of the reasons:

- no proper geological surveys were carried out before the house was built and the house was either built on weak soil or the soil was poorly prepared before the foundation was built;

- the house was built without the installation of drainage;

- the foundation is overloaded due to incompetence in the reconstruction;

- water supply, sewerage or heating systems have weakened the soil;

- in the event of the subsidence of the floor, the base surface has not been properly compacted during the foundation.

How to repair the subsidence of the foundation or the floor?

If it has been established that the foundation and floors of the house are subsiding, it is necessary to think about raising the building. For someone who has never heard of restoring and raising a foundation before, such work can seem like a very time-consuming and big project to take on. One may wonder if such a thing is possible at all and how big of a crane is needed for it? You might be left alone with a feeling that you have to choose between bad and worse. You can start with the tasks that are the most time-consuming and money-consuming or postpone solving the problem to an uncertain future while knowing that the situation is getting worse?

An easy solution would be to pour concrete over the subsided floor surface. This might seem like a good way to level floors. In reality, this can cause more damage, as fresh concrete adds new weight to soft ground and subsidence can continue even more intensively. Secondly, the building cannot be used while the concrete is drying.

Removing people or workers and things from the house and dismantling and reassembling the tools seem like a big task to take on. That is why raising and stabilizing the foundation should not be postponed.

What if restoring a foundation, raising a concrete floor or a log house, or stabilizing a building is actually a clean and quick process that does not require additional preparations such as moving out of the home? What if the cracked walls and cracks between the walls and the floor tiles could be fixed in one day, without having to wait for the new concrete to harden?

These are the questions that URETEK Baltic, a leading geopolymer soil remediation company in Baltic countries, has answers for. URETEK uses geopolymer injection technology, which allows for an innovative and convenient approach to the above-mentioned problems. URETEK technology has a wide range of applications and can be used to raise concrete floors, lift the entire log house or even an apartment building, level the ground, and stabilize the foundation. The technology offered by URETEK specialists ensures fast, convenient, and environmentally friendly lifting of the building, and the problem can be solved without disturbing the customer’s daily life and business.

How do URETEK geopolymers help to raise and stabilize the foundation?

Due to innovative technology, the work carried out by URETEK is a highly valued alternative for raising and restoring the foundations or floors of buildings. Such technology has many advantages over conventional methods, which are more complex from both a human and an environmental point of view. Geopolymeric injection differs from conventional building lifting procedures- it does not require excavation or demolition work, thus contributing to both human comfort and environmental protection. Also, URETEK technology does not cause vibration or disturbance.

When using the geopolymer technology offered by URETEK, the subsidence is stopped quickly. The essence of soil problems, which is the cause of the subsidence of the foundation and floors, is reached through a 12-32 mm wide borehole, and an ecologically neutral resin or geopolymer resin mixture is “injected” into it. The resin is introduced into the soil, where it expands until it hardens, filling in all gaps and cavities in the soil. During the resin injection, the house or other structure will rise higher if possible and return to its correct position. It is not necessary for people to move out of the house or even remove furniture from the building for this procedure. The building can continue to be used during the work process. It usually takes only one to three days to complete and the work area remains clean and free of dust.

The material that is used is a patented geopolymer resin blend. In order to increase the load-bearing capacity of weak soils, the unique expansion properties of the geopolymer resin mixture can be used, which quickly and efficiently restores the building to its original condition. Geopolymer is a strong, insoluble and time-resistant material that doesn’t damage the building’s structures. Geopolymer resins can fill any surface.

It may be thought that the polymer, as a chemical, could have a toxic effect on the soil or contaminate the water in the soil. URETEK technology has been used for more than 40 years. A number of scientific studies and experiments have been carried out on the safety of these materials. The results confirm that the fear of pollution is not backed up. The materials are safe for both humans and nature. Everything is regulated and certified according to European standards

URETEK technology is seen as an environmentally friendly approach. As URETEK technology does not require demolition or excavation to lift the foundation, does not require the transport of large materials or the use of large vehicles- it reduces CO2 emissions, saves resources and preserves nature. If there is a need to dispose of material, the process is no different from disposing of other building materials. Just like bricks, concrete or other construction materials, polymers are regulated construction waste that must be disposed of at construction waste collection points.

So it is confirmed that the procedure carried out by URETEK saves time and money and is an environmentally friendly solution to the problem of the subsidence of the load-bearing structures of the building.

Under standard conditions, URETEK provides a 2-year warranty for the work performed, and the material itself has a warranty of 10 years. At the same time, experience shows that objects stabilized 40 years ago remain solid and secure to this day.

The price of URETEK service depends on many factors, from the nature of the problem to the size of the foundation of the object. Visual assessment of the problem, consultation and initial underground inspection of the object are free of charge. After a visual inspection and inspection of the underground soil, a personal price offer is prepared for each customer.

URETEK team offers a free professional consultation to assess the condition of the load-bearing structures of the building.

URETEK Baltic compacts the soil

Stages of soil compaction:

- Visual inspection and survey by URETEK specialist, during which, the initial survey and inspection are carried out in order to understand the size and nature of the problematic area. After the visual observation and survey by URETEK specialist, an initial price offer can be made for the client. Visual observation and survey are free of charge for the client.

- If necessary, the soil under the flooring is inspected. In case, that the problem is more serious, a hole is drilled in the floor with the consent of the client, and a camera will find the empty spots under the floor, which have caused the floor and the building to subside. The initial underground inspection is free of charge for the customer.

- Geological research is done if necessary – in some cases, it is also necessary to carry out geological research of the soil to map out the state of the soil, which can be ordered by the client or with the help of specialists of URETEK Baltic. A geological survey shows what soil is under the building, how deep is the problem, and what is the nature of it.

- If the terms and the final quote work for the client, a time plan is agreed upon with the client, and work begins.

Keywords

Comparison of concrete works and URETEK technology. Pros and cons

Causes of deformation in building foundation

Formerly, foundation was repaired by cementing, now a new solution is used – URETEK technology. It represents a rapid and secure alternative to concreting and piling of foundation. URETEK technology deploys unique strengthening methods for foundation repairs, somewhat similar to advanced surgery. This technology allows eliminating the reasons for structural subsidence and deformation by re-levelling slab covering of concrete foundations, strip foundations, pile foundations and floor slabs and even solving problems related with access roads.

Work process

URETEK resin is inserted in the soil under a structure through small holes (usually with diameter of 16 mm, only 12 mm in case of interior works).

Then URETEK resins expand, filling cavities, compacting subsoil and stabilising the foundation (or other load-bearing structures), thus allowing re-levelling of the house.

For optimum results and safety purposes, the pressure generated in the course of expansion is constantly checked with laser equipment.

- Cracks in the walls usually shrink. However, in case of brick wall, it only requires secondary treatment of joints with mixture or joining with special fixture, patching and painting of cracks in case of plastered walls.

- Windows and doors will usually function normally again.

- Gaps between floor slats and fixed floors generally disappear as well.

Guarantee

Materials used comply with strict ecological and safety requirements and have been designed specifically to resist drying and subsidence. Quality is guaranteed for more than 50 years.

Strengthening methods using concrete works

Over many years, concrete works have been used as a classical method for foundation repairs. Compared to traditional concrete works, the advantages of URETEK technology include speed, cleanness, durability and predictability, economic efficiency and an opportunity to avoid interfering with normal use of the structure.

URETEK material ensures durable soil stabilisation and building re-levelling faster than concrete works, where nothing can be guaranteed. Now it is possible to heave a house to desired height within a day or two, or a couple of weeks, depending on its construction technology. Furthermore, resin injection does not generate waste, there is no need for excavation works, water, cement or concrete.

It is important to mention that injection works do not require vacating entire room. Unlike concrete works that need lots of preparation and interior works, URETEK technology does not need any of that. Small holes (diameter of 12–14 mm) can be drilled between cover plates and even through carpeting and there is usually no need for moving the furniture.

URETEK method is ideal for foundation repairs even in case of clay and other porous soils, as it solves subsidence problems. The method ensures load-bearing capacity of substrate and uniform properties of load-bearing layers.

In the course of concrete works, it is necessary to improve poor soil conditions, such as unbound, dusty and wet substrate or substrate containing poorly compacted filling material. This is due to the reason that extra weight of concrete may further aggravate the situation.

Cost of concrete works

Besides being more convenient, safer and durable, URETEK injection solution is usually also cheaper than traditional concrete base.

The cost of concrete works depends on many factors, including:

- Location of building,

- Actual cause of the problem,

- Properties and condition of the soil under a structure,

- Type and profile of building foundation,

- Surroundings, e.g. access to the plot, adjacent buildings and support walls,

- Unknown, unpredictable condition of the soil under a structure,

- Quantity of required material,

- Time spent on work.

If only one corner of the house requires re-levelling, concrete base may be cheaper, but it may still lead to further problems over time. For instance, new cracks may develop in the house if concreting is performed in only one section of the foundation, not to mention additional load on the base affecting the substrate that was used to former loads.

In most cases, resin injection is cheaper than other methods, including concreting of foundation.

Keywords

Restoration of historical monuments

Sites of great historical and cultural value are threatened by natural ageing and going to ruin just like any other structure.

Sites belonging to national and global cultural heritage must be restored or reconstructed to keep structural damage to minimum, be it then repair of walls and floor or lifting and strengthening of foundation. Damage of historical buildings can be minimised by using URETEK geopolymers technology.

Manor buildings and palaces, castles and fortresses, churches and temples, but also many other sites of historical interest age, break down and go to ruin. Condition of walls, roofs and ceilings of the building is affected by constantly alternating external factors: pressure, temperature, humidity and airborne gases.

Equally dangerous are changes in soil on which the site of historical interest has been erected. Thus, weakening of soil under the structure may cause subsidence of ground floor and reduce stability of foundation, which leads to damaging other structural elements of the structure.

Complications related to strengthening soil

Subsidence of foundation and floor of sites of historical interest often causes occurrence of cracks in floor and walls. In that case, simple cosmetic repairs of walls and floor are not enough to improve the situation, because the cause of cracking is not eliminated. Without improving the condition of substrate and lifting foundation or floor, the situation continues to worsen and may ultimately result in complete destruction of architectural monument.

Although sites of historical and cultural interest are generally renovated by using state-of-art technologies and building materials, lifting of floors and strengthening of foundation in these structures is often performed using traditional methods. However, traditional technology along with involvement of heavy machinery and concrete and earthworks may damage the site of historical or cultural interest.

Elimination of cracks in the floor and walls of an architectural monument, as well as strengthening of substrate and lifting of foundation or floor is much more efficient when using URETEK geopolymer resins injection technology. That technology makes it possible to perform works without affecting the historical and cultural value of the site and also reduces the budget for repair and restoration procedures.

Provided technology

There are two URETEK geopolymers injection methods that can be used for strengthening the soil under historical monument and eliminating floor and foundation subsidence – Deep Injection and Slab Lifting. In the first case, geopolymer material intended for strengthening the soil and lifting the foundation is inserted deep into the soil under the structure, in the second case geopolymer is inserted immediately under ground floor.

Geopolymers are injected in soil or under the floor through special pipes with diameter of 12–16 mm, inserted in holes drilled in ground floor or soil around the perimeter of the building. Borehole diameter may be 12–32 mm. No other interventions are required on the site. The equipment for injecting geopolymer resins is compact and mobile. Using it has no effect on the historical or cultural value of the site. Injection holes can be easily eliminated later on.

All procedures performed with URETEK geopolymer resins, be it then strengthening of soil, securing or lifting foundation or floor, do not take long. After injection, geopolymer material expands, filling all cavities in soil and hardens within just 15 minutes, exerting vertical pressure. Lifting of foundation and floor is monitored in real time by using laser level.