Resistance to cracking is definitely observed when studying the durability of reinforced concrete structures. Builders can ascertain the resistance of the studied material to various internal and external factors. This indicator is expressed by the amount of time until the occurrence of first cracks. The longer the period when the structure remains intact, the greater the resistance of material to cracking. Crack develops when the stress factor significantly exceeds material’s permitted threshold value.

Accurate estimation can be obtained only by expert assessment of concrete samples. That currently most efficient method of study predicts future durability of the structure.

Factors affecting resistance of concrete to cracking

Occurrence and progression of minor defects in concrete can be induced by external factors – humidity and temperature – as well as the properties of the material itself. Determination of resistance to cracking takes into account information regarding the quality, flexibility, creep, settling and other properties of the material. Important factors include structural form and dimensions of the building.

Furthermore, the technology of manufacturing the cement must be considered. Materials with low hardening speed develop cracks less frequently cracking. That is why determination of resistance to cracking is a rather complex process and requires versatile analysis.

Options for increasing resistance of concrete to cracking

Even the appearance of small cracks in concrete structures is considered rather dangerous. Minor damages may cause cement to chip off, leaving the fixture exposed. This leads to corrosion, which causes further degradation. Concrete can be made more durable by using the following methods:

– using additives with special strengthening properties;

– magnetisation of water;

– inspecting the composition of concrete;

– covering the surface with iron;

– installing a special protective layer to avoid occurrence of small cracks;

– creating concrete with the best possible structure for particular purpose.

Optimum concrete composition requires using correct ratio of chosen components, which makes the concrete structure more durable.

If the crack has already occurred

Prior to repairing concrete structures, it is important to ascertain the cause of cracks. Restoration works can be divided in two:

– repair of structural defects;

– erection of new structures to replace the damaged parts.

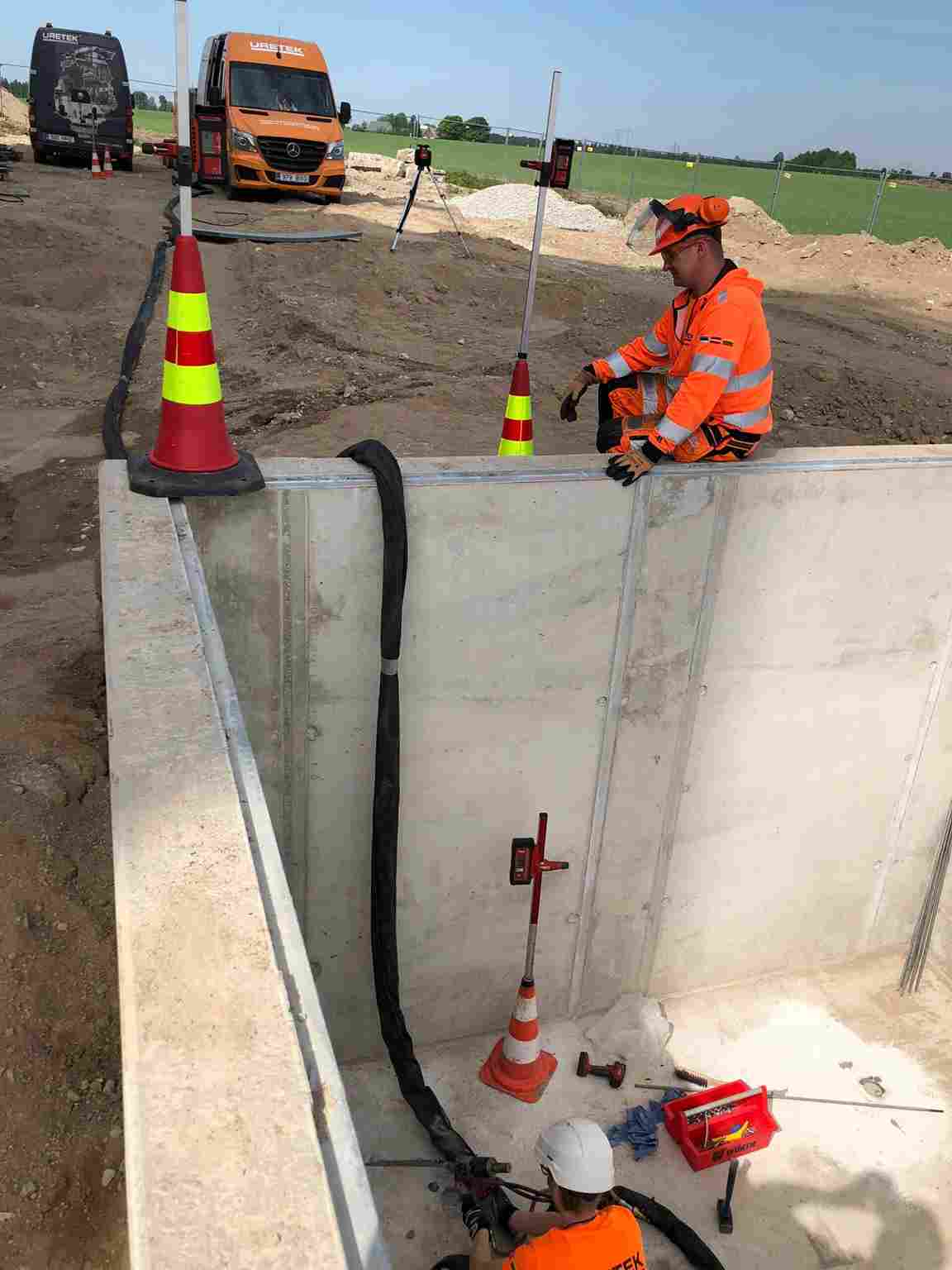

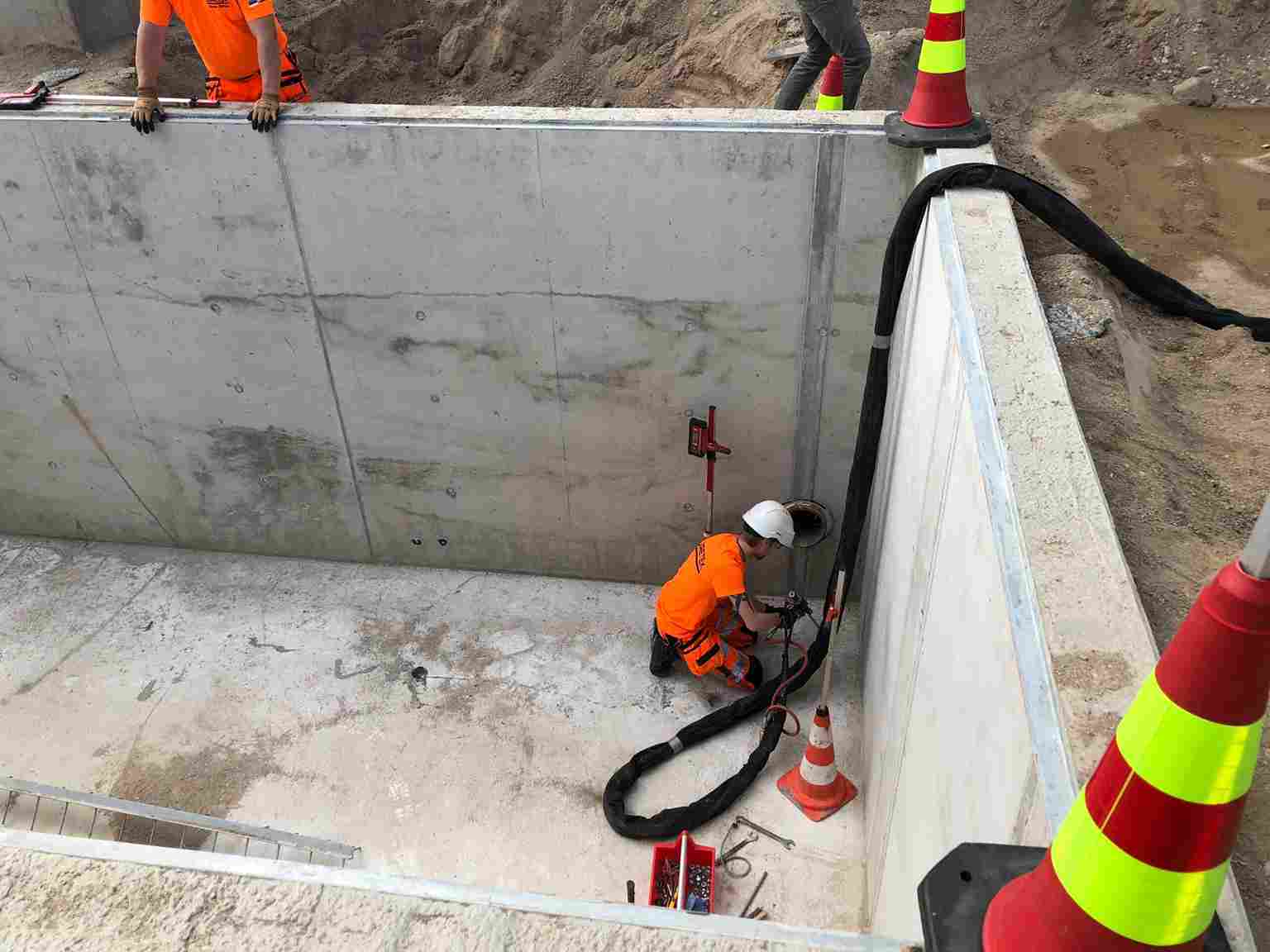

Injection method represents optimum way of removing cracks. Special mixture is inserted in the problem area by using pressure. Where it is necessary to restore protective layer, shotcreting method is used. In that case a special construction mixture is prepared, which is then applied to prepared surface under pressure.

If the defects occur due to the soil, the problem needs to be solved urgently by strengthening or stabilising the subsoil.

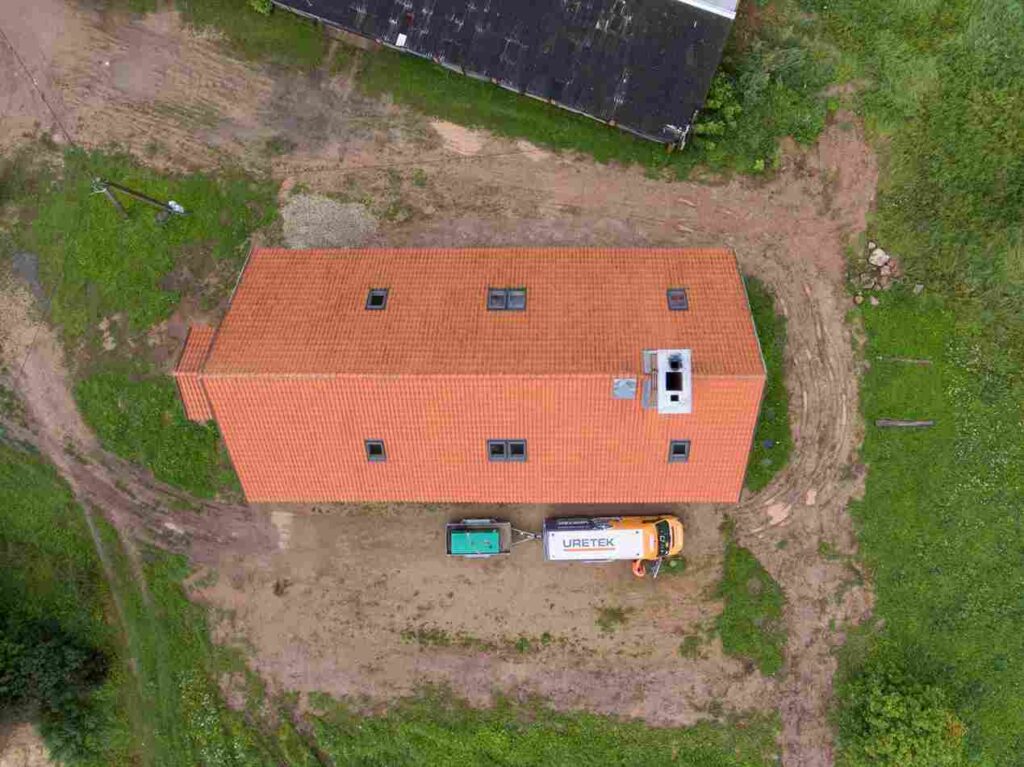

URETEK specialists have everything they need to analyse, repair and restore concrete structures. When you contact us for help, every client may consider all their problems solved.