Local utility companies and government bodies are responsible for a large number of facilities from roads and bridges to water supply, sewerage and drainage systems. In order to ensure the safety and efficient uninterrupted servicing of residents, it is crucial to keep these facilities in good working order. Continuous monitoring and technical servicing is important not only for occupational safety and efficiency, but also from the aspect of long-term reliability.

According to a recent study, interruptions in the provision of main utility services such as electricity and water supply have great impact on both business and domestic activity. Additionally, deterioration of the condition of main and minor roads can reduce expediency of freight transport, increase costs related to servicing of vehicles and increase risk of accidents.

After realising the increase in the cost of maintaining and renovation of infrastructures, many European local governments and public bodies have recognised URETEK’s innovative technological solutions as fast and most sustainable method to maintain and restore various objects that often have complex structure.

When choosing suitable solution, it is important to consider factors affecting the safety, ease of use and durability of infrastructure objects. Examples of innovative solutions provided by URETEK for servicing infrastructures:

Stabilisation of public buildings and underground infrastructure

URETEK’s non-invasive resin injection technology was used when building Moskva City to fill large cavities and voids adjacent to heating main and restore the soil under a structure, increase load-bearing capacity of the soil and prevent its further subsidence. In the course of these works, heating pipeline was efficiently stabilised and supported within less than a week, without disturbing the functioning of adjacent pipelines.

Clients often address URETEK to stabilise state and public structures suffering from uneven land subsidence under the foundation. For instance, after discovering the sinking of the foundation and floor of a building belonging to local government used as a restaurant in Belgorod oblast, causing large cracks in the walls, URETEK managed to restore the building in an operative and sustainable manner. Lifting, re-levelling and supporting of the building took only ten days when using geopolymer resin.

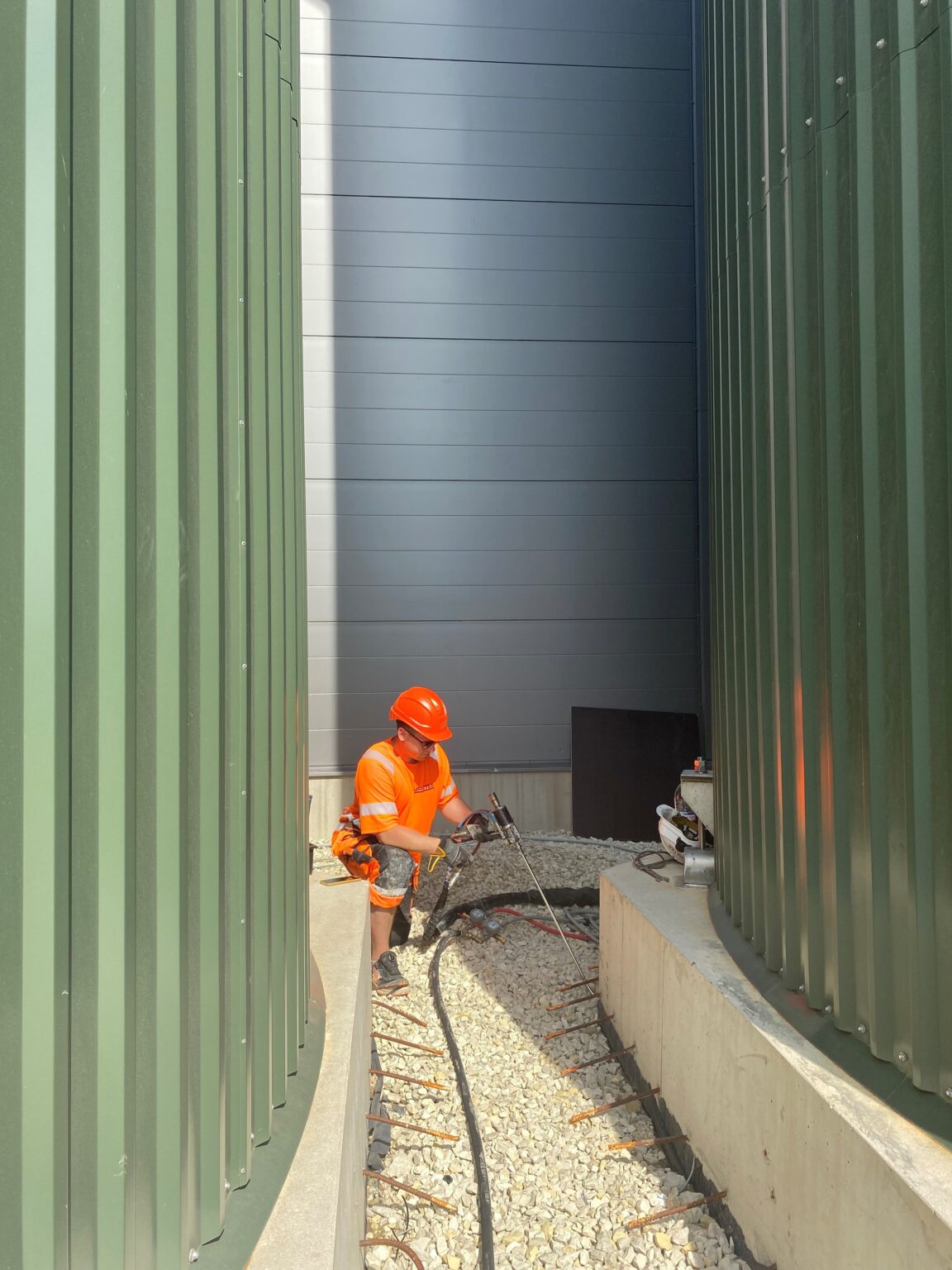

Discarding of reserve pipes

URETEK light resin represents a tried-and-tested and innovative solution for filling bulky pipes and other technical reservoirs to be discarded. In Kuzbass region, URETEK technology was used to fill an underground water pipeline in the course of modernising a mineshaft. URETEK geopolymer is so-called flowing material, which can be pumped at great distances (when expanding, the material achieves incredibly high compressive strength at minimum density). Many clients have admired the material’s ability to fill large voids, cavities, pipes and reservoirs quickly and cost-efficiently.

Rapid expansion of the cities of the Russian Federation causes increasing burden on infrastructure. Thus, it is more important than ever to ensure durability of structures in long the long term, while also keeping in mind the impact that solutions and measures applied today have on the quality of structures intended for the future generations.