Geopolymers do not react with water, they remain stable even in humid environment. This allows using geopolymers for levelling and strengthening of jetties, embankments and berths.

URETEK geopolymer resins are suitable for stabilising infrastructure objects of seaports and river ports. In order to lift concrete structures and stabilise them, geopolymers can be injected under the concrete slabs of jetties, embankments and berths as well as in water-saturated subsoil of these structures.

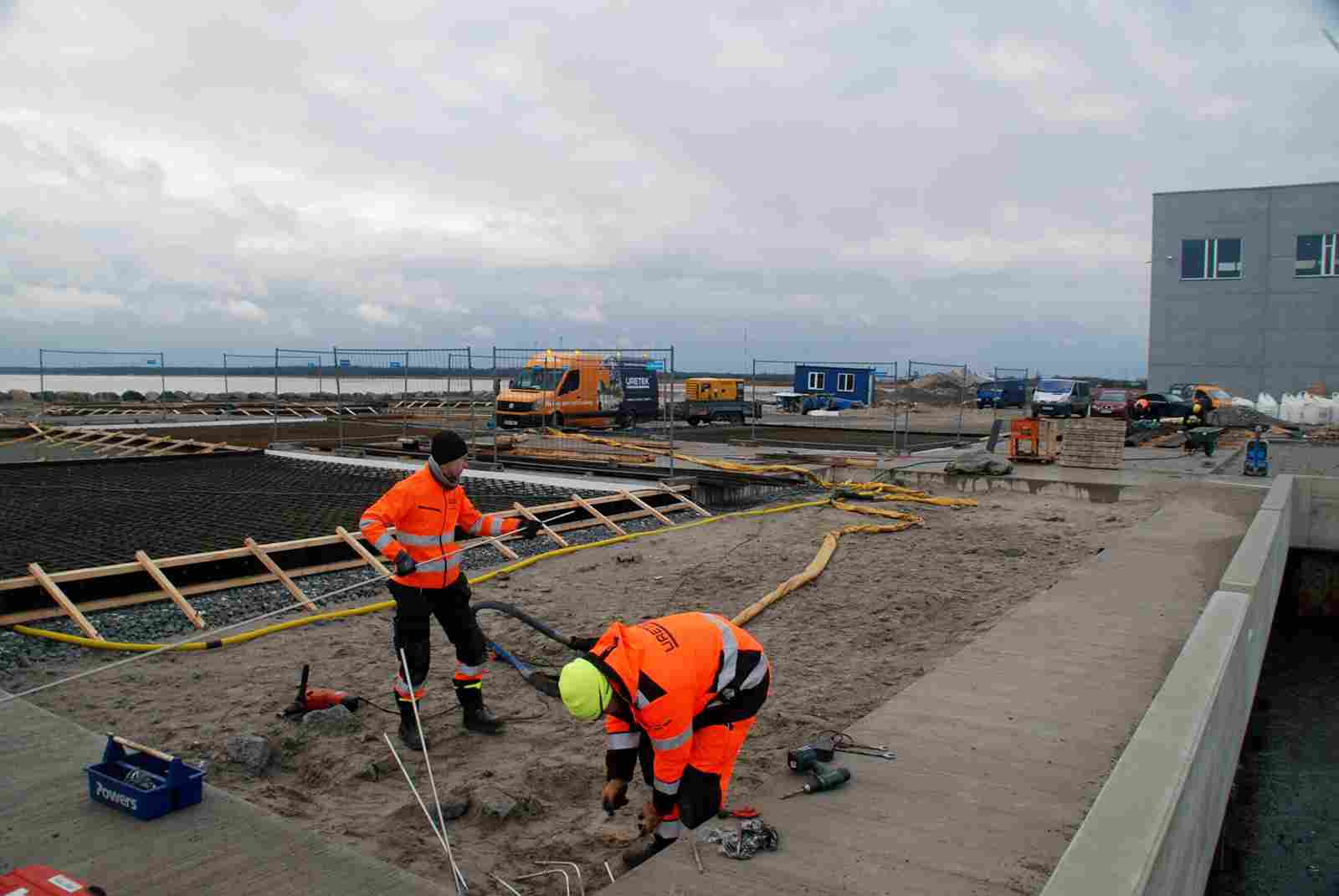

Strengthening the soil under jetties, embankments and berths

Construction of concrete jetties and embankments generally requires installation of a vertical support wall that would retain filling material necessary for installing concrete slabs. Due to constant water influences, surface water level changes dynamically, meaning that there are also changes in the moisture content of soil under the structure.

As a result of that, filling material can slowly become more compact and horizontal surfaces are subject to movement and uneven subsidence. Concrete slabs of jetties, embankments and berths are also affected by heavy duty vehicles, gantry crane, transporters, loaders and other additional loads. Total weight of port loader with transmission container reaches up to 100 tons. Naturally, such weight causes increased compaction of the filling material under concrete base and soil under the entire structure. Thus, different sections of concrete surface may suffer from uneven subsidence.

In order to level concrete slabs and stabilise the structure of jetties, embankments and berths, filling material and subsoil of the structures must be strengthened. Load-bearing capacity of soil is improved with geopolymers in stages and without disrupting port operation.

Lifting and stabilisation of concrete slabs

URETEK geopolymer resins are suitable for levelling and strengthening of parking lots and manoeuvring areas for heavy duty vehicles, loaders and gantry cranes. Furthermore, geopolymers can be used to repair concrete floors and covers of port warehouses and docks, the condition of which has deteriorated due to exposure to water.

Concrete slabs are levelled by using Slab Lifting method. For more efficient stabilisation of port structures, Deep Injection method is used. It enables strengthening of soil under the structure. Geopolymers force out excess water, thus increasing the load-bearing capacity of soil.

Advantages of URETEK methods

Formerly, repair of concrete surfaces meant removal of all cover slabs, compacting of filling material and reinstallation of concrete slabs. In that case, major repairs are similar to new port construction, involving not only high cost, but also long-term stoppage of port operations, causing additional costs and loss.

URETEK technology makes it possible to perform work without dismantling concrete slabs and interrupting port operations. Materials and equipment required for geopolymer injection fit in a single truck. For injecting geopolymers under concrete slabs and deep in soil, holes with diameter of 12–16 mm are drilled. These holes are simply closed later. Stabilised and repaired sections can be used 15 minutes after completion of works.